Fabrication is more than just a fancy term that describes the process of putting things together. It’s an artistic venture; encompassing both science and craft. Imagine the complexity of transforming raw materials into finished products—from intricate metal parts to simple household appliances; the railroad bridges and tracks. Fascinating, isn’t it?

What is Fabrication?

Fabrication is defined as the act of constructing different items/materials such as metal, sheet, laminates, wood, and other solid surfaces together. These raw materials can be manufactured into items like engines, machines, tools, and household appliances by using different fabrication processes. Additionally, fbrication often includes steps such as cutting, stamping, shearing, rolling, machining, and others.

As with other manufacturing processes, fabrication can be done manually. However, with how swiftly technology advances, processes are now often automated with the use of computer programs such as computer-aided designs (CAD). Hence, the need for manpower such as CAD Operators. The use of such technology helps reduce lead times, costs, and material usage.

How Fabrication Works

The fabrication process involves a series of steps that all serve different purposes. However, the first stage of any fabrication project is design.

Albeit it is possible to use hand-drawn designs for simpler work, CAD programs enable more complex and detailed processes such as prototyping, which helps a lot in the visualization of products.

The Role of CAD in Fabrication

What is the role of CAD in fabrication? CAD (Computer-Aided Design) plays a pivotal role in the fabrication process by providing numerous advantages that enhance efficiency, accuracy, and cost-effectiveness. Through CAD software, fabricators can create detailed and precise visual representations of their designs, allowing thorough analysis and refinement before any physical work begins. This significantly helps identify potential issues early, saving both time and materials.

Different Fabrication Processes

Fabricators use a range of processes depending on the product specifications and materials. Here are some of the key processes involved in the majority of fabrication projects:

Burning and Cutting

Burning and cutting tools are essential because they are used to cut through raw materials. Here are some of the most common burning and cutting techniques used in fabrication.

Forming

Forming is the process of using force to change a flat sheet of metal into a 3D part without adding or subtracting material. This process is controlled by machines to ensure repeatability and accuracy. Industries that make the most out of machine-controlled forming are those within the aerospace, automotive, construction, and architecture sectors.

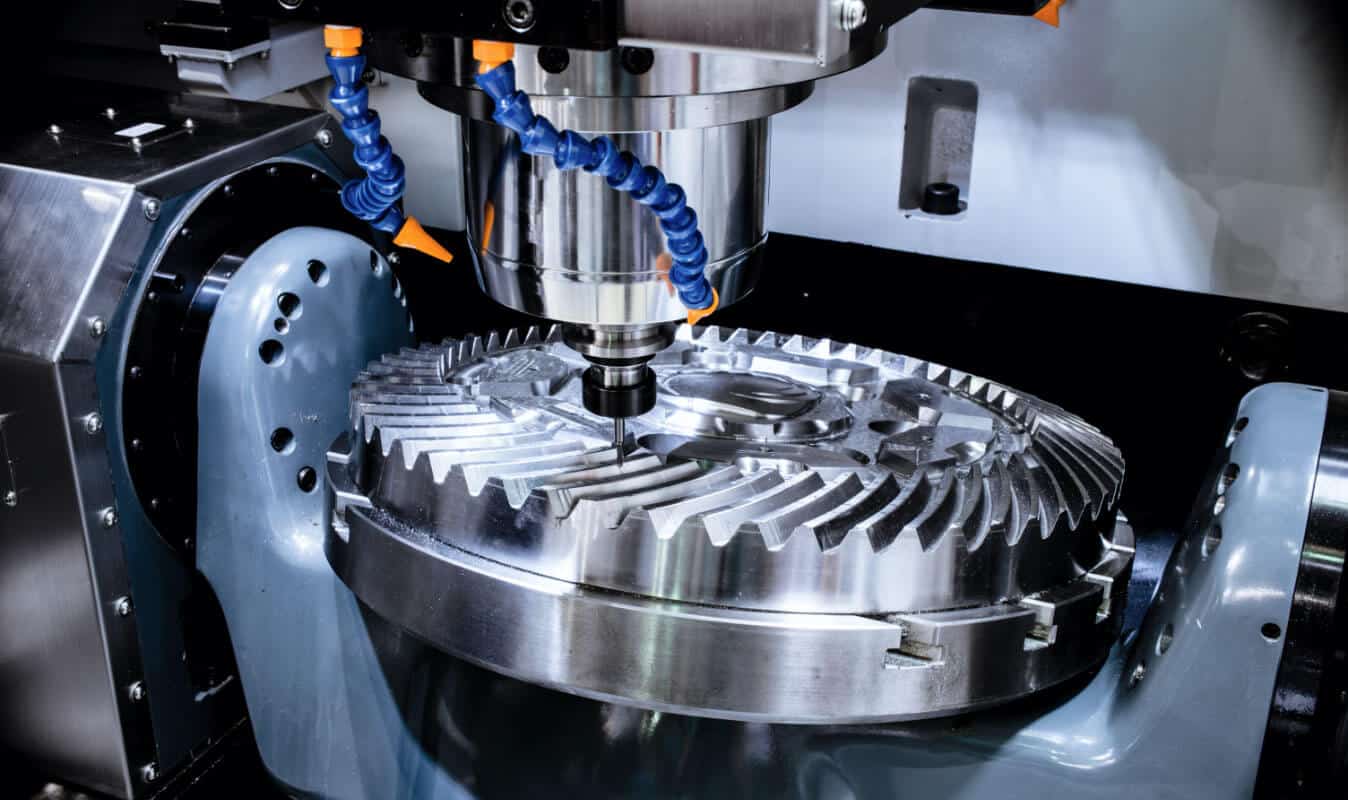

Machining

Machining is removing material from a solid block to create a desired shape. This includes lathes, mills, and drills. Solid items like bolts, screws, and nuts are common products of machining.

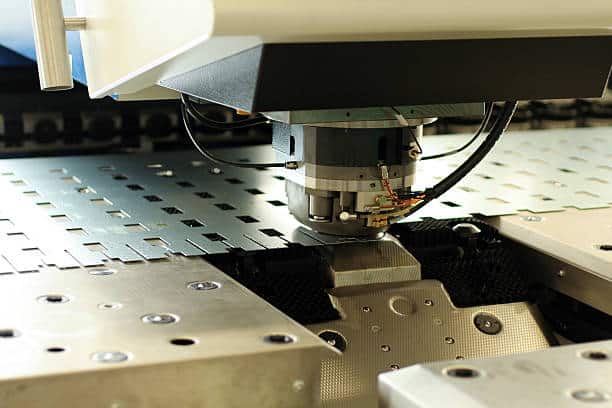

Punching and Stamping

Punching involves using a press to create holes in materials. Stamping, on the other hand, leaves an indentation that can allow shapes and patterns to be imprinted into the piece. Punching and stamping may be done hydraulically, mechanically, and/or mechanically.

Welding

Welding is the foundation of many essential industrial processes because it plays a critical role in construction, manufacturing, and metalworking. Naturally, it becomes the primary process in many fabrication projects as well; it joins formed and machined parts to create a final product. If you want to master the basics of welding, TOTC Inc. offers top-notch welding training courses. Just send us a message.

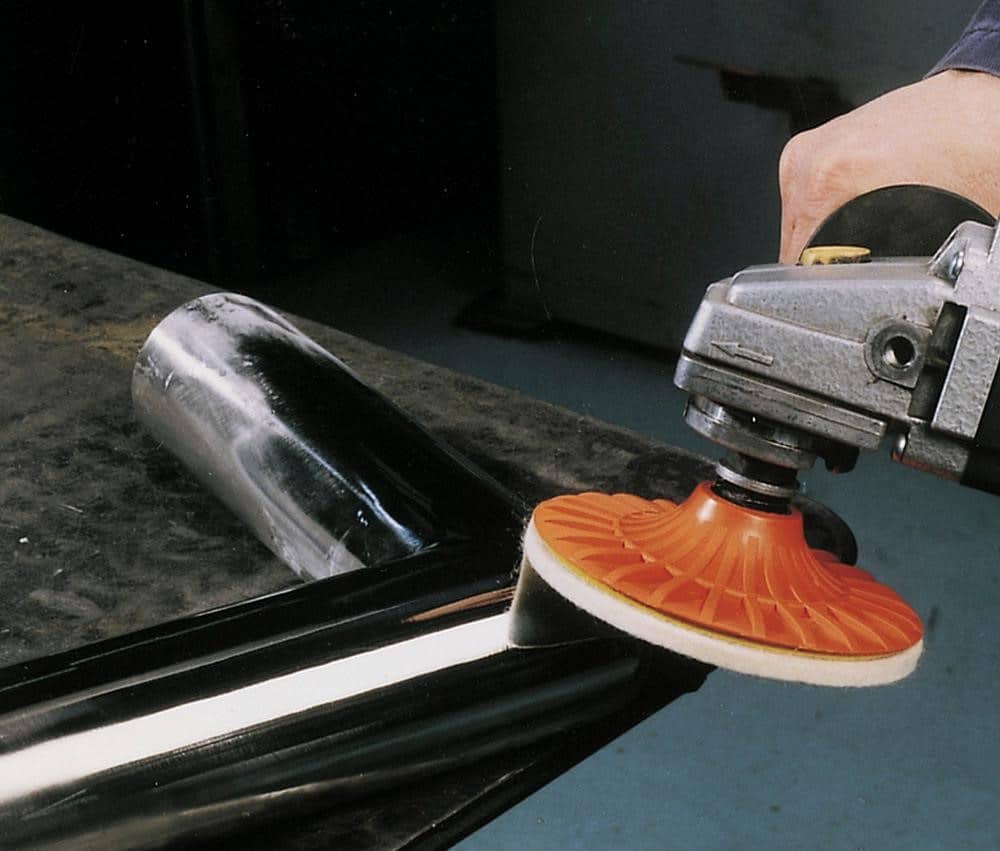

Finishing Touches

Finally, once a product is formed, it often undergoes finishing processes to improve appearance and durability. This can include coating, painting, and polishing.

Applications of Fabrication

Fabrication isn’t just limited to large metal structures. It plays a crucial role in creating components for engines, machines, tools, and household appliances. Here are some of the applications of fabrication across the many industries in the Philippines.

Industrial Applications

Aerospace

Fabricated parts for aircraft

Automotive

Components for vehicles

Construction

Metal structures and frameworks

Farming Applications

Farming Equipment

Replacement pieces for an old tractor and other farming equipment

Manufacturing Industry

Boiler, Tank, and Shipping Containers

Assembly parts that make up a ship

Architectural and Structural Metals Manufacturing

Used to form structures of buildings

Structural Beams

Fabricated metals that make it easier to erect buildings

The Role of Fabricators

Fabricators are skilled professionals who bring designs to life. They must understand various materials and processes to create high-quality fabrication projects.

Challenges in Fabrication

As much as the most skilled fabrication professional makes fabricating look easy, some challenges limit their capacity to produce fabrication projects to the fullest.

- Material Limitations – Different materials have unique properties that can pose challenges. As a result, fabricators need to understand these properties to avoid issues like cracking or warping.

- Precision and Accuracy – Maintaining high levels of precision and accuracy is crucial, especially in automated processes. Because for every production process, even minor errors can lead to significant issues in the final product.

- Safety Concerns – Fabrication involves dangerous equipment and materials. Ensuring a safe working environment is paramount to prevent accidents and injuries.

Conclusion

Fabrication is an essential part of modern manufacturing, transforming raw materials into finished products through various processes. Fabrication is also crucial for producing a wide range of items we use daily, from household appliances to industrial machinery. It enables the creation of complex structures and components that are essential in modern society.

With advancements in technology and automation, the industry continues to evolve, offering greater efficiency, accuracy, and quality. Whether it’s creating components for a spaceship or a simple kitchen appliance, fabrication plays a crucial role in bringing ideas to life.

TOTC Inc. is a Rising Fabrication Services Provider

If you’re looking for a service provider, you need a partner capable of meeting all your requirements. Factors to look out for are experience, expertise, and workmanship—all of which are qualities we guarantee as part of TOTC’s work ethic. Furthermore, our fully-equipped in-house facility and state-of-the-art technology guarantee clients fabrication projects that are second to none.

Send us your requirements for dependable and high-quality fabrication services!

Learn more about our fabrication services and what projects we are amenable to doing by visiting our page on Fabrication Services.

Great explanation about fabrication with examples.