Fabrication work is vital in various industries, from construction to manufacturing. Understanding the nuances of fabrication work demystifies the process and highlights its importance in our daily lives. This blog post will explore critical aspects of fabrication, including its purpose, scope, and safety considerations.

What is Fabrication Work?

In our previous blog, we discussed what is fabrication work. But to explain it again, fabrication work refers to putting together or assembling raw materials, often by cutting, shaping, welding, or machining, to create finished structures and products. This practice is essential in construction, automotive, aerospace, and many others, where metallic materials such as steel or aluminum are used for machinery or buildings.

Of course, such an application is not limited to metals. Plastic fabrication is also a prominent practice. Regardless of the materials used, the core idea remains the same: fabrication brings an idea to life through careful planning and skilled labor.

What Is the Purpose of Fabrication Work?

The primary purpose of fabrication is to create functional products and structures, like a steel beam for a building or an automobile component. Fabrication work is the backbone of many industries. Modern construction and manufacturing would not be possible without fabrication, as it provides the essential building blocks for various applications.

In addition, fabrication allows for customization. Each project has unique specifications and requirements, and fabrication enables manufacturers to produce tailored solutions. For example, custom metal brackets can be designed for a specific machinery application.

What Does Fabrication Work Include?

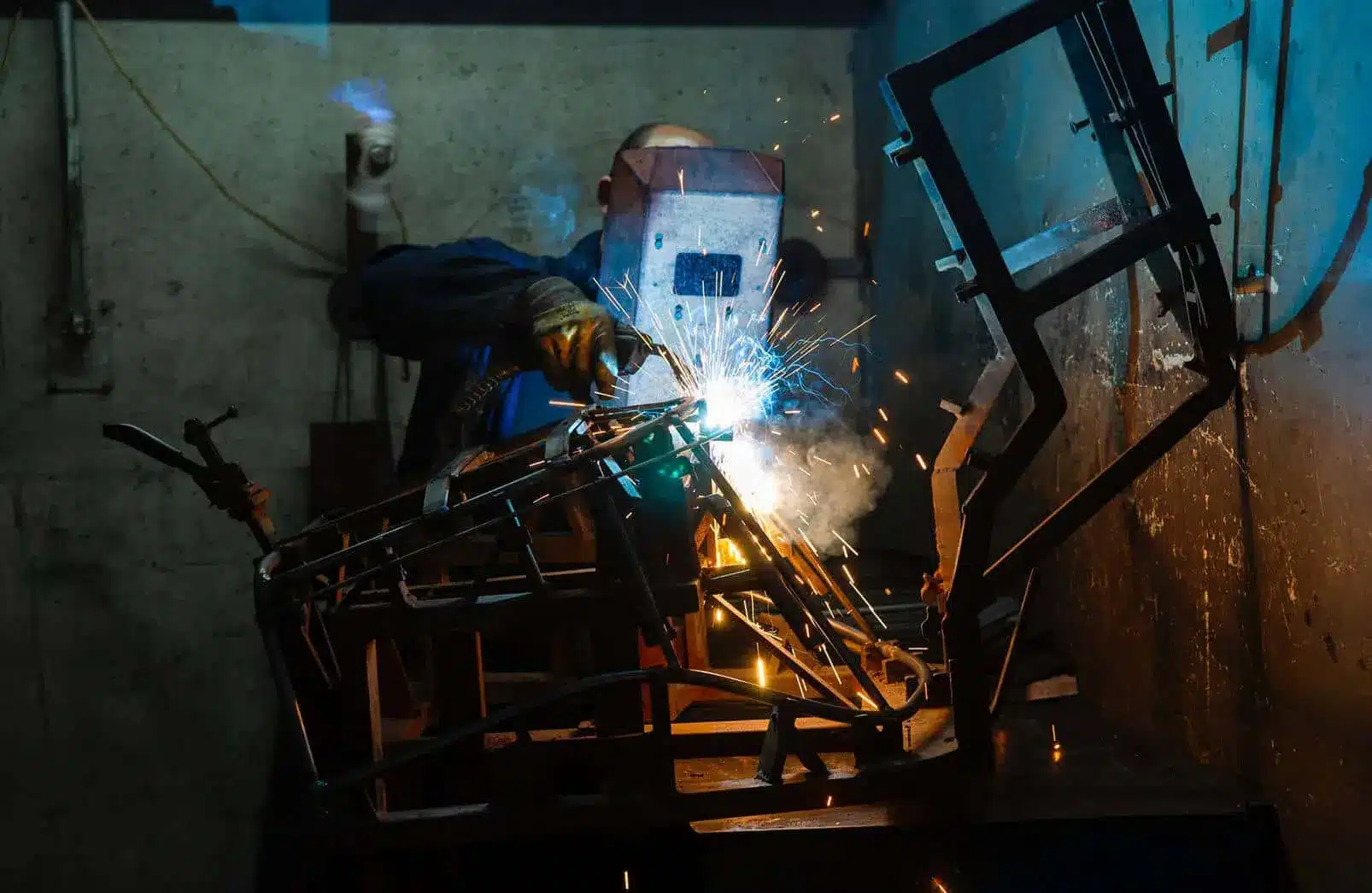

Fabrication work encompasses a variety of processes and tasks. Generally, it includes cutting, bending, welding, and assembling materials. Each of these processes is essential to transforming raw materials into finished products. For instance, cutting involves using tools to slice materials into precise shapes while bending shapes materials to create desired angles.

Furthermore, welding is a crucial aspect of fabrication. It combines materials using heat and pressure, ensuring the finished product is solid and durable. This technique is commonly used in metal fabrication, where pieces must withstand significant stress and load. In addition to welding, assembling involves assembling various components, often using fasteners or adhesives to secure them.

Fabrication work also includes surface treatment and finishing processes. These steps improve the appearance and durability of the final product. Techniques like painting, galvanizing, or anodizing protect materials from corrosion and wear, enhancing their longevity. Thus, the scope of fabrication work extends beyond mere assembly; it encompasses a comprehensive range of activities designed to deliver high-quality products.

What Industry Does Fabrication Work Belong To?

Most people get confused about this. Fabrication spans multiple industries. For example, the construction industry heavily relies on fabrication to produce structural components such as beams, columns, and frames.

Furthermore, the automotive industry depends on fabrication to create engine components and body panels. Precision and quality are critical here, as even minor defects can compromise vehicle performance. Fabricators in this sector often use advanced technologies, such as laser cutting and robotic welding, to meet these high standards.

In addition to everything mentioned above, fabrication plays a vital role in the aerospace industry. Aircraft manufacturing requires stringent quality controls and highly specialized fabrication techniques. Components must be lightweight, solid, and durable to withstand harsh conditions. Consequently, the aerospace sector often employs advanced materials and fabrication methods, including composites and additive manufacturing, to achieve these goals.

Is Fabrication Considered Construction?

Many people wonder whether fabrication is considered construction. The answer is somewhat nuanced. Fabrication is a component of the construction process. However, fabrication itself is not synonymous with construction. Instead, it is a foundational step that supplies the necessary components for construction projects.

Construction typically encompasses a broader range of activities, including site preparation, foundation laying, and assembly of fabricated components on-site. Whereas fabrication usually occurs in a controlled environment, such as a workshop or factory, where specialized tools and equipment can be utilized effectively.

Therefore, while fabrication is integral to construction, it is merely one aspect of the overall process.

Is Fabrication Manufacturing?

Similar to the previous bullet, fabrication, and manufacturing represent different scopes of work. The difference is that fabrication focuses on creating components or products from raw materials, whereas manufacturing encompasses the entire process of producing goods, from initial design to final assembly.

Both sectors rely on professionals with expertise in various techniques to ensure that products meet quality standards. As industries evolve, the intersection of fabrication and manufacturing will likely become even more pronounced.

Safety Considerations in Fabrication Work

Workers in this field often handle heavy machinery, sharp tools, and hazardous materials. So, implementing safety measures is crucial to prevent accidents and injuries. Proper training, personal protective equipment (PPE), and adherence to safety protocols can significantly reduce risks.

First and foremost, workers should receive thorough training on the equipment they will be using. Understanding how to operate machinery safely is essential to minimizing accidents. Wearing the appropriate PPE, such as helmets, gloves, and eye protection, also provide safety against potential hazards. Regular safety audits and drills can further reinforce the importance of safety in the workplace.

Moreover, maintaining a clean and organized workspace can prevent accidents. Cluttered environments increase the risk of slips, trips, and falls. Fabricators can create a safer working atmosphere by storing tools and materials correctly and ensuring that walkways are clear. Ultimately, prioritizing safety protects workers and enhances overall productivity and efficiency.

Common Fabrication Hazards

Considering fabrication is a labor-intensive practice, this naturally means that it is not without its occupational hazards. Fabrication work can pose risks to workers. Common hazards include exposure to hazardous materials, machinery-related injuries, and ergonomic risks.

1. Exposure to Hazardous Materials

First, workers are susceptible to hazardous materials, such as chemicals used in welding or cutting processes. Prolonged exposure to these substances can lead to serious health issues. Therefore, proper ventilation, safety data sheets (SDS), and appropriate handling procedures are essential to mitigate these risks.

2. Machine-related Injuries

Second, machinery-related injuries are prevalent in fabrication. Workers often operate heavy equipment like lasers, CNC machines, and welding tools. If proper safety measures are not in place, accidents can occur. Regular maintenance and machinery inspections and adherence to safety protocols are vital to reducing the likelihood of equipment-related incidents.

3. Ergonomic Risks

Lastly, ergonomic risks can arise from repetitive motions and awkward postures. Workers engaged in tasks like lifting heavy materials or performing repetitive actions may experience musculoskeletal disorders. Implementing ergonomic practices, such as proper lifting techniques and providing adjustable workstations, can help alleviate these risks. The fabrication industry can foster a safer and more efficient working environment by addressing common hazards.

Choose a Trusted Fabrication Services Provider Like TOTC Inc.

Choosing the right fabrication services provider is crucial for ensuring high-quality results. A reputable provider should possess the expertise, equipment, and certifications to handle various fabrication projects. Moreover, they should be able to offer customized solutions tailored to meet specific client needs.

When selecting a custom fabrication services provider, consider a provider with a proven track record. Communication is also critical when working with a fabrication services provider. A collaborative approach allows for a better understanding of project requirements and facilitates problem-solving. Regular updates and open lines of communication can significantly enhance the overall project experience.

In conclusion, partnering with a reputable fabrication services provider can make all the difference in achieving successful outcomes.